Richard McMahon from Down Under introduced us to this idea as follows:

From: richard mcmahon

Date: Fri Jul 4, 2003 2:23 am

You may get greater efficiency by using your surplus solar electricity

to turn a stirling-cycle engine. But even more effective would be the

following, based on the fact that you get surplus solar electricity

when the sun is shining: Set up two cylinders (1 and 2), each

containing a displacer linked so that they can move together in phase.

Your surplus solar electricity can move the displacers backwards and

forwards and the only work required is to overcome friction (say in the

range of 10 to 50 watts) Then rig up a flatplate or trough parabola

solar thermal collector to heat the hot end of cylinder 1. U

se either fins or water to cool the other (warm) end of cylinder 1

to ambient, and also to cool the (warm) end of cylinder 2) to ambient.

The other end of cylinder 2 will get very cold indeed. This is heaps

cheaper than photovoltaics to turn a motor on a compressor as you are

mostly using low grade solar thermal energy.

Have fun

Regards

Richard McMahon faq@solarmirror.com |

From: Marc Ringuette

The Vuilleumier cycle is like a "non-kinematic duplex Stirling omitting

the shared piston".

Hey Richard, let me try and explain the cycle. I'll use the orientation

of the following ascii-gram (hot side to the left). I'll refer to the

four spaces as A, B, C, D as follows:

hot side | A | displacer | B ==ambient== C | displacer | D | cold side

The entire device is built inside a single pressure vessel, which cycles

up and down in pressure once per cycle of the displacers, with all

parts of the system at the same pressure at any given time.

The displacer cooler cycle

---------------------------

Phase 1 (solar heating). Both displacers are stationary to the right.

As the air in space A is heated by the sun, pressure gradually increases.

This increase is transmitted to all parts of the system. The air in

space C is heated by compression, but cooling is applied to keep

the temperature in space C near ambient. When the pressure hits our maximum...

Phase 2 (air movement). Both displacers are moved to the left, moving

the air from A to B and from C to D. Ideally, each displacer should

act as a heat exchanger, cooling the air further and storing the heat for phase 4.

Richard, I suggest using the displacers as regenerative heat exchangers

(make them out of perforated metal, so that they store and release heat

once per cycle).

Phase 3. (cooling). Both displacers are stationary to the left.

As the air in space B is cooled by heat exchange with ambient,

pressure gradually decreases. This decrease is transmitted to the

rest of the system, where the air in space D is cooled by expansion,

and is able to absorb heat from the cooling load. When the pressure

hits our minimum...

Phase 4 (air movement). Both displacers are moved to the right, forcing

the air from B to A and from D to C. Ideally, the displacers will have stored

some heat from phase 2 and will pre-heat both masses of air ("regeneration").

Return to phase 1.

-------------------

I really like the fact that this can happen as slowly or as quickly as the

heat exchange can occur. I'm imagining a large one of these built inside

a 1000 gallon propane tank, cycling every few minutes. One end of

the (long cylindrical) tank is solar heated, one end is used for cooling,

and the middle portion is water-cooled to near ambient.

Richard, congrats, this is very promising! It's a way to use solar

heat directly in a compression based cooling system ... without any

intermediate steps involving electricity or mechanical work. Nice!faq@solarmirror.com |

Kudos to Randal Perisho (and his anonymous Stirling engine friend)

who clued us in that this is called the Vuilleumier cycle.

Online references:

There is exactly one good online reference so far.

"Development of a gas fired Vuilleumier heat pump for residential

heating", by H. Carlsen (Denmark)

http://ieeexplore.ieee.org/iel5/852/2490/00074788.pdf

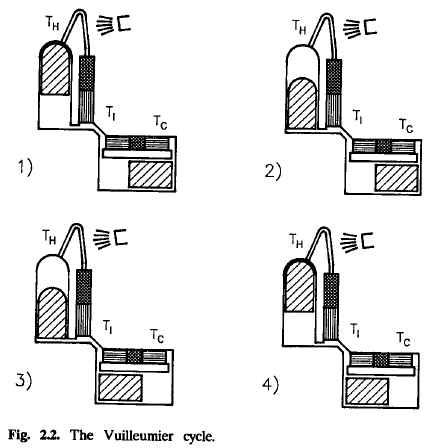

(the above diagram, and the one earlier, are from Carlsen's paper.)

(Note: the diagram indicates that the "cool" displacer is moved

first, then the "hot" one. There needn't be a time delay between

the two moves, but this seems like a good choice in order to keep

a large fraction of the useful expansion (and harmful compression)

in the correct chamber of the "cool side".)

----

I should also mention these two nice little Stirling simulations,

in case you'd like to learn (or remind yourself) how those work.

They run in your web browser as Java applets.

http://techni.chemie.uni-leipzig.de/stirling/

http://www.suction.co.jp/stirling/seMove/yamaMove.html

--Marc Ringuette

----

Offline references:

Stirling and Vuilleumier Heat Pumps by T. R. Roose et al., 1990, 256 p.

http://www.stirmach.com/Books4.htm

there is also this book:

Regenerative Thermal Machines (Stirling and Vuilleumier Cycle Machines)

for Heating and Cooling, by Noboru KAGAWA, Dr.

http://www.bekkoame.ne.jp/~khirata/book_ref/index_e.html

Also, Brad Ross, the SMW editor, is a really good guy, and extremely

knowledgable about all things stirling. he would be the best guy to

point you to a good source of info. --Chris, the maniacal engineer

(the above diagram, and the one earlier, are from Carlsen's paper.)

(Note: the diagram indicates that the "cool" displacer is moved

first, then the "hot" one. There needn't be a time delay between

the two moves, but this seems like a good choice in order to keep

a large fraction of the useful expansion (and harmful compression)

in the correct chamber of the "cool side".)

----

I should also mention these two nice little Stirling simulations,

in case you'd like to learn (or remind yourself) how those work.

They run in your web browser as Java applets.

http://techni.chemie.uni-leipzig.de/stirling/

http://www.suction.co.jp/stirling/seMove/yamaMove.html

--Marc Ringuette

----

Offline references:

Stirling and Vuilleumier Heat Pumps by T. R. Roose et al., 1990, 256 p.

http://www.stirmach.com/Books4.htm

there is also this book:

Regenerative Thermal Machines (Stirling and Vuilleumier Cycle Machines)

for Heating and Cooling, by Noboru KAGAWA, Dr.

http://www.bekkoame.ne.jp/~khirata/book_ref/index_e.html

Also, Brad Ross, the SMW editor, is a really good guy, and extremely

knowledgable about all things stirling. he would be the best guy to

point you to a good source of info. --Chris, the maniacal engineer faq@solarmirror.com |

(diagram from http://ieeexplore.ieee.org/iel5/852/2490/00074788.pdf )

(the above diagram, and the one earlier, are from Carlsen's paper.) (Note: the diagram indicates that the "cool" displacer is moved first, then the "hot" one. There needn't be a time delay between the two moves, but this seems like a good choice in order to keep a large fraction of the useful expansion (and harmful compression) in the correct chamber of the "cool side".) ---- I should also mention these two nice little Stirling simulations, in case you'd like to learn (or remind yourself) how those work. They run in your web browser as Java applets. http://techni.chemie.uni-leipzig.de/stirling/ http://www.suction.co.jp/stirling/seMove/yamaMove.html --Marc Ringuette ---- Offline references: Stirling and Vuilleumier Heat Pumps by T. R. Roose et al., 1990, 256 p. http://www.stirmach.com/Books4.htm there is also this book: Regenerative Thermal Machines (Stirling and Vuilleumier Cycle Machines) for Heating and Cooling, by Noboru KAGAWA, Dr. http://www.bekkoame.ne.jp/~khirata/book_ref/index_e.html Also, Brad Ross, the SMW editor, is a really good guy, and extremely knowledgable about all things stirling. he would be the best guy to point you to a good source of info. --Chris, the maniacal engineer